The Issue

Although Derby Station had an amount of refurbishment work carried out in 2013, this did not provide the electrical infrastructure to accommodate a £200M upgrade with new island platforms. The specification required 2 new public access lifts to be installed along with platform lighting, public address systems, passenger information displays and full fire protection. New electrical distribution was also required to provide electrical supplies to retail units long the platforms and several public welfare facilities.

A strong element of project planning, communication between engineering teams and professionalism was an absolute requirement, as the many different trades employed to deliver this project had to conduct their works in close proximity to one another. This would also require working around the clock and at weekends to minimise disruption to a live operating railway station and meet the demands of the project programme period.

The Solution

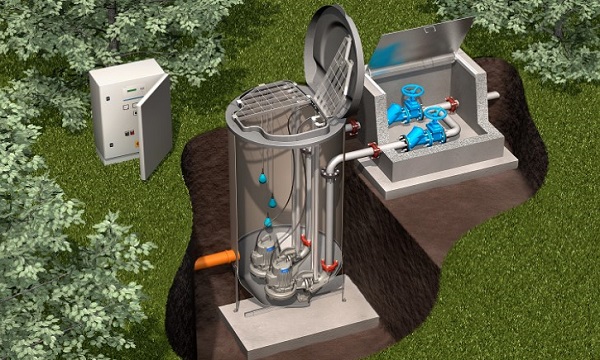

With the extensive experience of Kemada’s Project Management team in the Rail sector, Galliford Try appointed Kemada to deliver the electrical package. This required our engineers to conduct an electrical shutdown to enable the DNO to upgrade the transformer supplying the station. From the main distribution panel, Kemada provided 2 new electrical supplies from platform 1 to platform 7, this was also required as a temporary power supply for the construction works and therefore, was a priority to kickstart the whole project.

The new island platform required lighting along the entire 320m length. This was achieved through 9no. 6m lighting columns, with twin LED lanterns for the open platform areas and over 100no. LED luminaries underneath the platform canopy, which covers 70% of the overall length. Kemada installed over 500m of CMS (cable management system) to accommodate the electrical, fire and SISS (Station Information & Security System) services.

Kemada engineers installed the electrical supplies for 2no. new access lifts, air conditioning systems, retail units, standard class and first class lounges. In order to maintain the project completion date, Kemada provided assistance with the installation of the CCTV cameras and CIS screens along the entire length of the new Platform 6 & 7.

The Outcome

With the project being conducted to a very tight deadline along with the challenges of the hottest summer on record, Derby Station Remodeling has been reported extensively, as a huge success.

150,000 hours of RIDDOR free works, new innovations and the motivation of highly experienced project managers across several market leading companies was the correct ingredients for this project to be delivered on time and in budget. This will benefit 4 million passengers who use this station every year and alleviate a ‘bottleneck’ in the network. Passenger and haulage trains will be able to traverse the Derby junctions at higher speeds reducing travel times.

As part of our ongoing commitment to maintain our accreditations to work in such high profile business sectors such as the Rail Industry, whilst also ensuring that our customers expectations for quality and standards are met, our electrical installation was inspected by the NICEIC (National Inspection Council for Electrical Installation Contracting) as part of our annual audit. The inspecting engineer was very impressed with the quality of work, documentation and certification stating; ’The outcome of the assessment is a pass result. From the site inspections it was noted that the electrical installation work has been done to a high standard – well done’.

Following our recent Rail Industry Supplier Qualification Scheme (RISQS) audit, where Kemada received the highest 5-Star status, this positive feedback was further testament to all the hard work and effort the project team put in to such a prestigious project.